We source our leather from a Tuscan tannery located between Pisa and Florence. Founded in 1975, the tannery shares our commitment to vegetable-tanned leather and maintains high production standards. Over the years, its philosophy has focused on continuous technological innovation to deliver high-quality leather while safeguarding the environment.

Vegetable tanning transforms raw hides into leather using natural tannins extracted from trees. Carried out over an extended period in rotating wooden drums, the process combines traditional craft with modern technology and machinery to produce a premium-quality material, with respect for people and the environment.

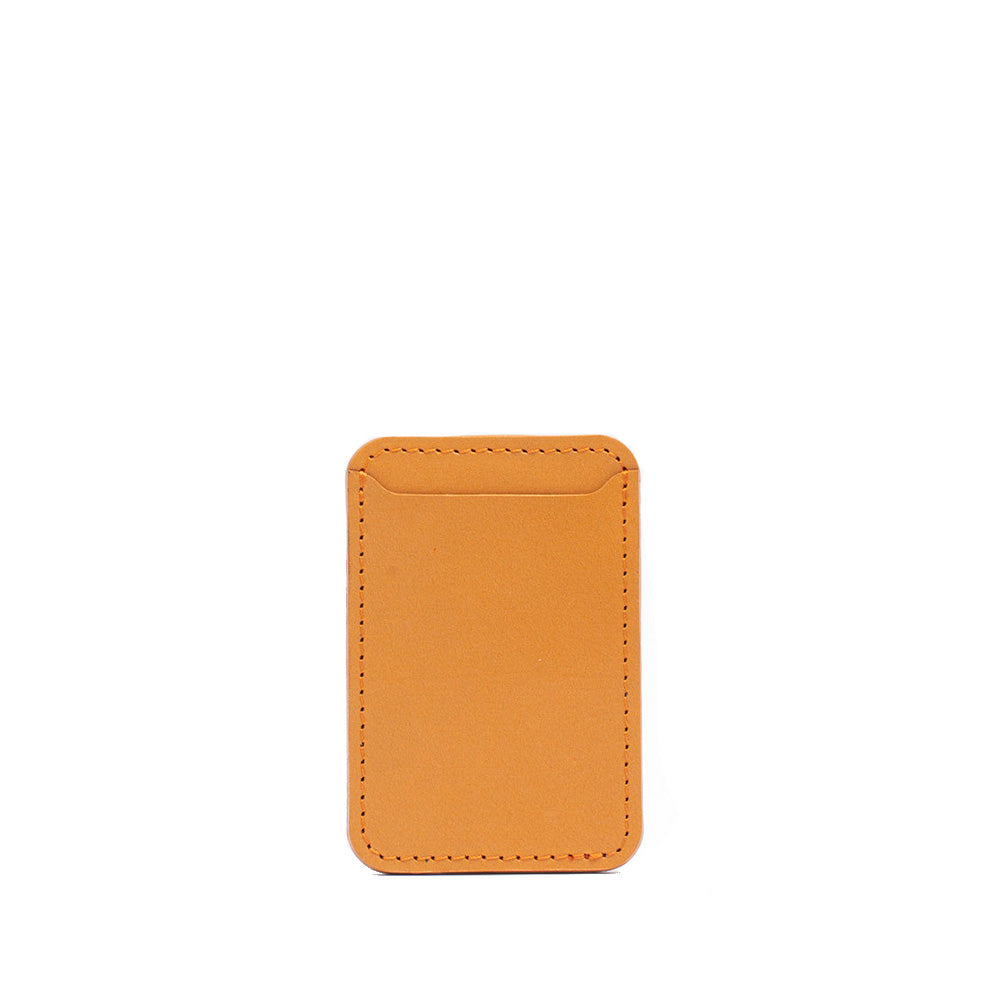

The leather we use is carefully selected for exceptional quality. We work with premium full-grain and top-grain leathers. Full-grain retains the hide’s original surface—no sanding, buffing, or snuffing—so the strongest fiber structure stays intact, preserving natural texture and long-term durability. Top-grain is lightly corrected for a more uniform look while remaining strong, flexible, and comfortable in hand. Both are chosen for longevity; full-grain, in particular, is naturally breathable and develops a rich patina over time.

Key characteristics that set our leather apart

• Among the most durable leather types, thanks to its intact fiber structure

• Natural in-hand feel with an authentic, premium touch

• Soft, supple temper that breaks in beautifully with use

• Varied texture across the hide—from smooth to naturally wrinkled/pebbled

• Visible natural marks and scars acquired during the animal’s lifespan (not defects)

• Subtle color variation (typically 1–2 tones) depending on the hide and cut area

TAN COLOR

BLACK COLOR

CAMEL COLOR

MAHOGANY COLOR

BROWN

GRAY